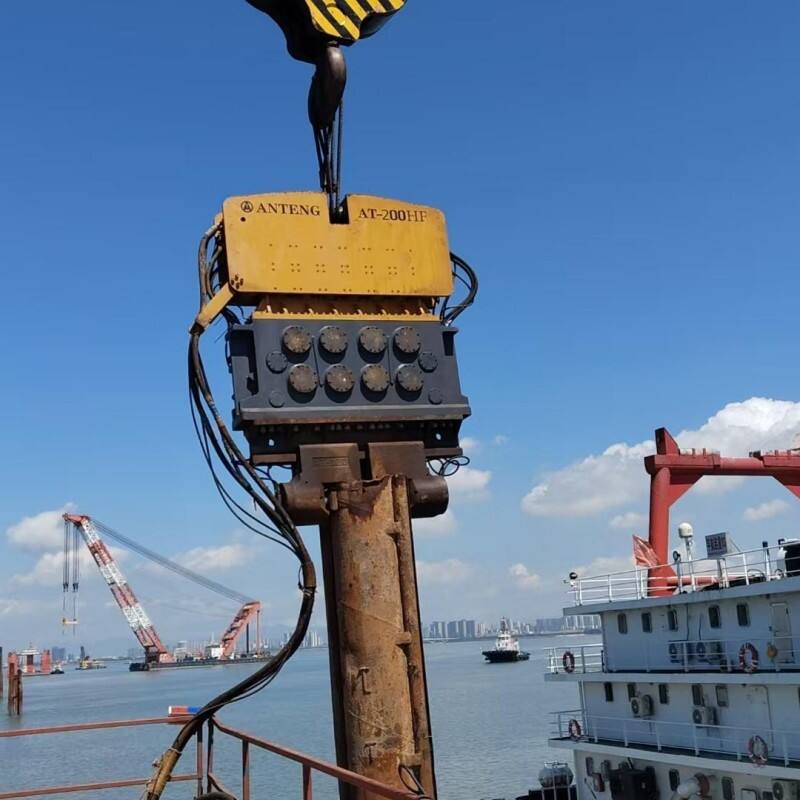

AT-200HF

| Specifications : | |

| Eccentric moment | 28 kgm |

| Max. centrifugal force | 1810 KN |

| Max. frequency | 2400 KN |

| Max. amplitude excl. ATJ240 | 16 mm |

| Max. amplitude incl. ATJ240 | 11.2 mm |

| Max. static line-pull | 600 KN |

| Max. operating pressure | 350 bar |

| Max. oil flow | 605 l/min |

| Max. hydraulic power | 353/480 kW/HP |

| Dynamic weight excl. ATJ240 | 3500 kg |

| Dynamic weight incl. ATJ240 | 5000 kg |

| Total weight excl. ATJ240 & hoses | 6400 kg |

- Application

- Introduction

- Features

- Recommended Products

|

|

|

|

Introduction: Anteng Hydraulic vibratory hammer is well developed piling equipment widely used in deep foundation pits, trenches, pipelines and real estate basements in ports, subway stations, tunnels, bridge cofferdams, bank protections, municipal engineering and civil engineering, with a very wide application in driving and extracting sheet piles, casing piles, H beam, pre-casted piles, etc. Anteng Hydraulic vibratory hammer range contains 2 main series, normal frequency and resonance free, and totally 19 models, eccentric moments varies from 28kgm to 250kgm, and centrifugal force varies from 1000KN to 5400KN. Other sized vibratory hammers are also available on request. The hammer is equipped with power pack adopting well-known brands of spare parts, such as Cummins and Weichai engine, Parker motors, Rexroth pump, FAG bearing, and so on, for ensuring high quality and stable performance. |

|

|

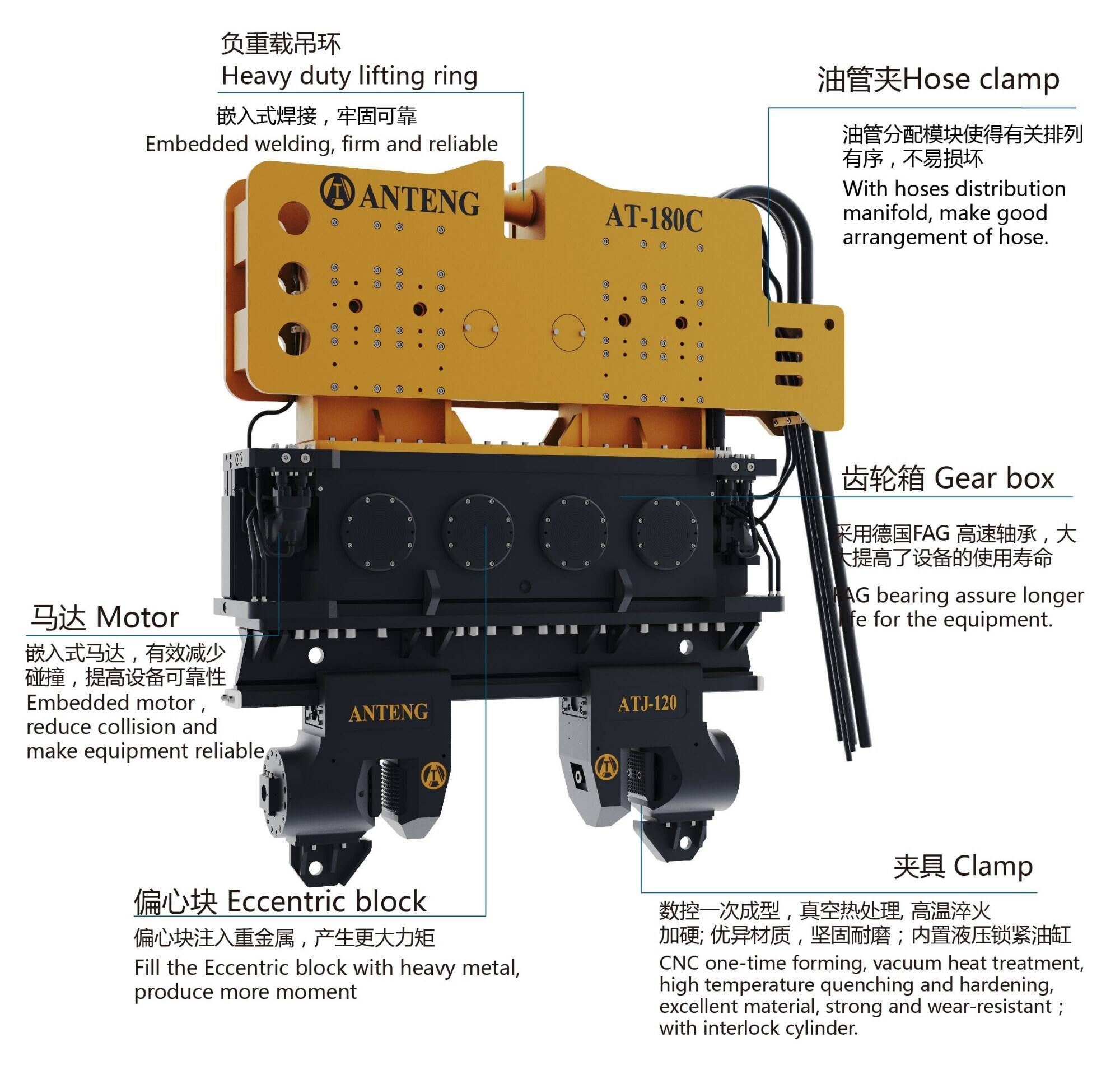

Heavy metal filled eccentric block Our eccentric blocks of hydraulic vibro hammers are filed with“heavy metal, that can produce more eccentric moment and bigger centrifugal force at same frequency. So our vibro hammers drive piles more efficiently. |

|

German FAG high speed bearing We adopts German FAG bearings, which have longer service life than ordinary bearing.This is key components to keep hammer working time. |

|

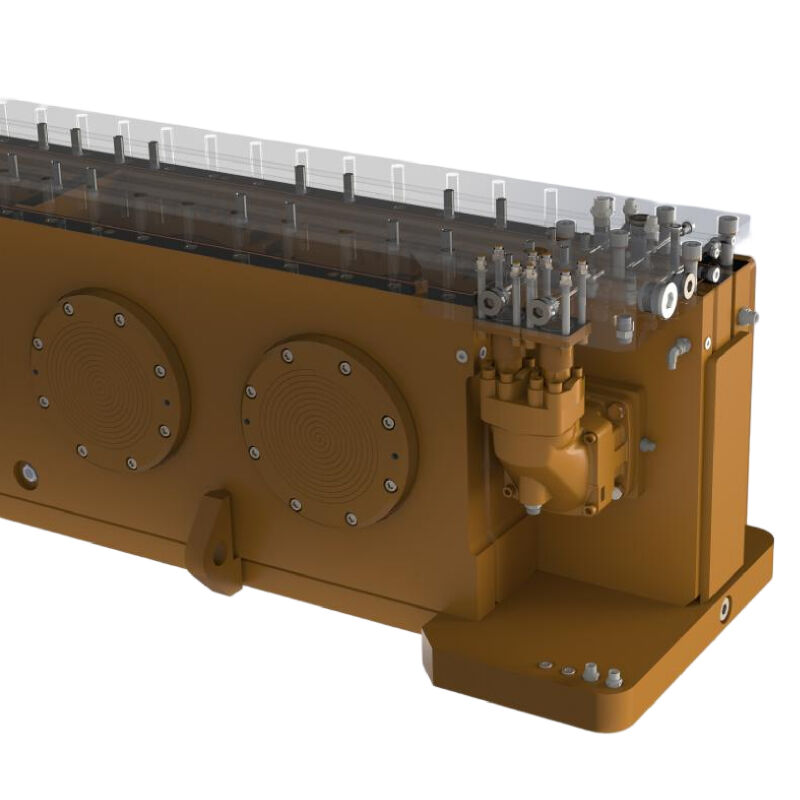

REXROTH hydraulic system Our all hydraulic pumps are from world top brand-Rexroth, which service life and performance stability are much better. |

|

Forced lubrication cooling system Forced lubrication system make gear parts of vibro hammer more fully lubricated and the temperature increase is steady. |

|

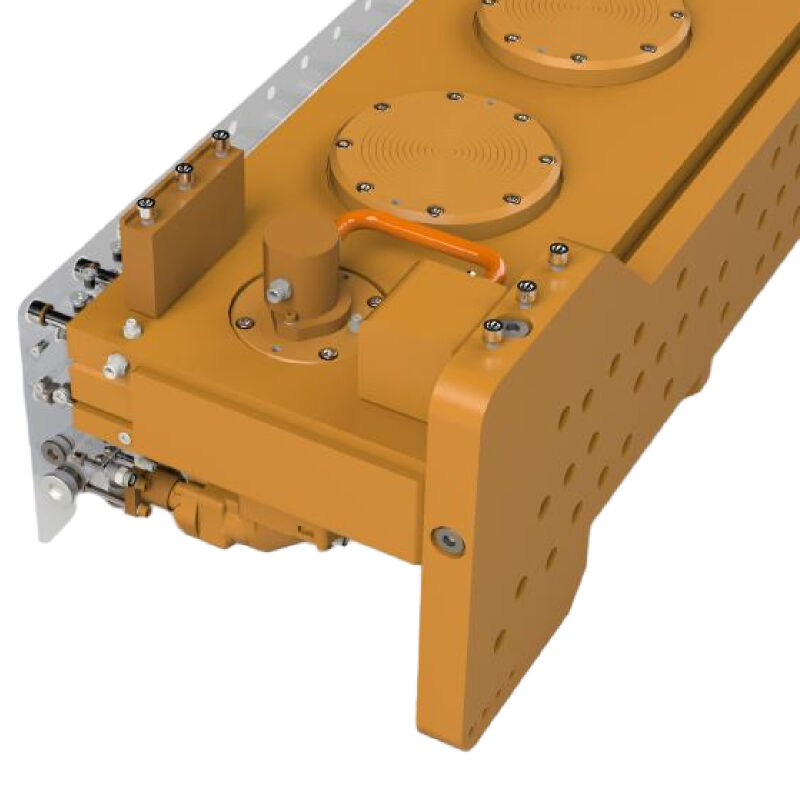

Build-in Oil circuit Hydraulic oil circuit is built in top cover of housing, eliminating 75% hoses and avoiding damaging while working, thereby reduce failure rate. At same time the structure of vibro hammer is more compact. |

|

Embedded motor Our hydraulic motors are embedded or with external protective shell, reducing the damage chance of the motors due to collision during the operation, and keep vibro hammers steady. |